this morning i fixed the 343 after it broke down last night (wouldn't run idle and ran terrible on partial load), found some dirt in the floaterchamber so i cleaned the carb completely up and all problems were solved.

then it was lunchtime and after that i started drawing out the following, wich i had to do 5 times this afternoon...

i couldn't get a method to weld that 3mm flange to 1mm pipe, preheating the flange worked best; but as soon as it cooled down the flange was warped as f*ck

i did found time for an actionpic though

after the oil return pipe i made a bracket for the wastegate actuator

rolled the shit outside:

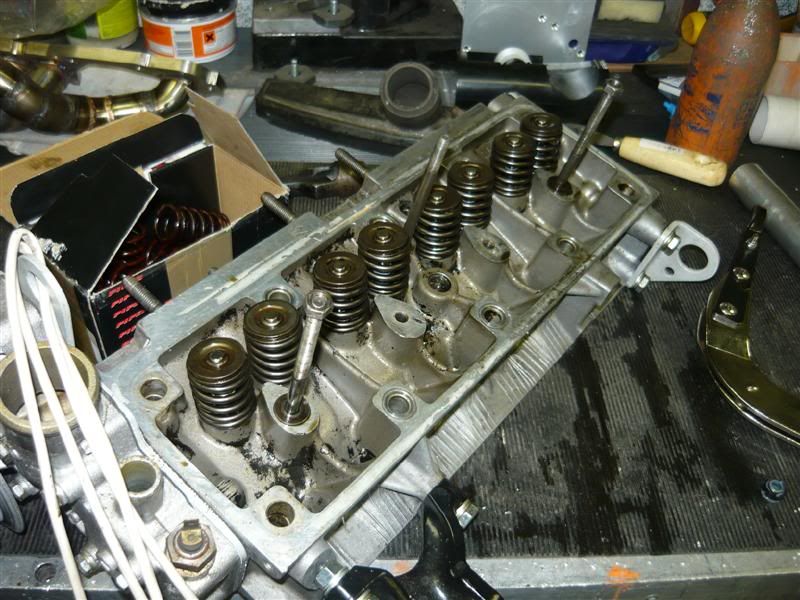

said a prayer and got the engine back in:

then i made a jump of joy; what a space left!!!

i'm very lucky; nothing i did has to be redone. this week i'm gonna lay out some parts to get powdercoating, on fridays i may get back to the engine. flatten out the oilreturnpipe, finish the actuatorbracket (mainly adding strength and mounting holes etc) after that i'm gonna start welding the manifold, and when that's done, a bigass bracket from turbo flange to an M10 bolt in the engine to support the manifold; in short words, more than enough to do!!!!