Yeah, just take it easy with the heat (i.e. once tacked, do it slowly, in short sections), and you shouldn't have too much trouble with deformation.

I was thinking that about the waxoyl

cheers

James

Filler.Speedy88 wrote:Oopla, get the filler outSo are you just going to put in some metal from behind or weld an extra section on the outside? I've often wondered the "right" way of going around this. I usually just keep welding until there's no more holes

Joke fail.volvosneverdie wrote:Don't do that man. It's had one million man hours.

And its only six month to summer.

Might as well finish it off.

I can indeed James, kept the very section that was cut out (and wished I could go back in time 2 minutes).foggyjames wrote:Ouch. Can you use part of what you cut off? I've found that the Swedish (or Belgian!) steel > Dutch steel > British steel. I usually keep a 7/900 or 850 panel kicking around as a source of quality steel for little bits like this.

cheers

James

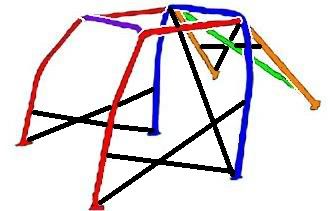

Spoke to a few people about these when I was pondering a SS exhaust system for a Chavleer aaaages ago.Limp wrote:What do we think? The place I have chosen to make the cage don't mess about, and know what they're talking about. I wouldn't use them otherwise!

I dropped the ballmacplaxton wrote:We think the post needs a bit of repetition editing out. Been on the sauce? :s