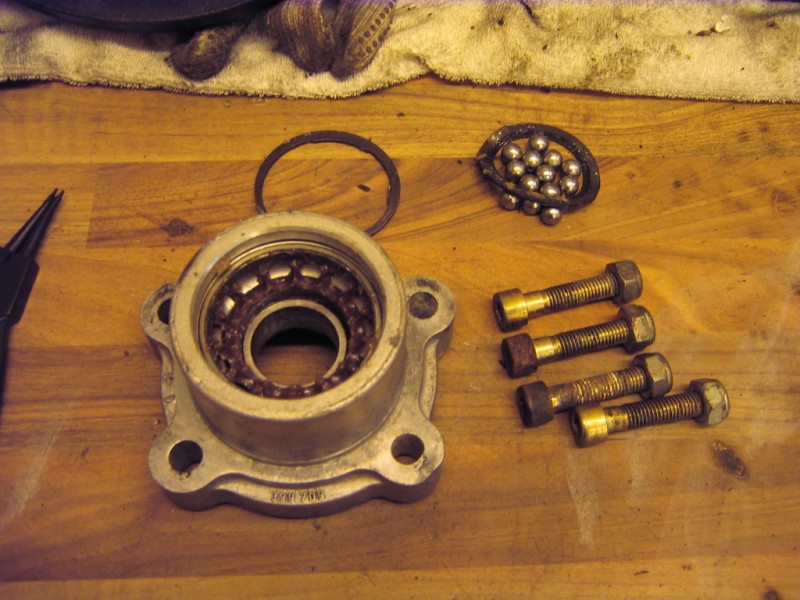

No this is what I am saying, on the later bearing you cannot remove the wheel flange/axle without damaging the bearing, its only held together by bits of plastic inside and the insertion force is much higher after it is clamped together by the drive flange and the big nut. The wheel flange and drive flange hold the inner parts of the bearing together strongly and the axle is tapered into the bearing inner and gets stuck (oddly the drive flange side is not tapered). There maybe a special Volvo tool that allows to be separated it but its not clear, likely it will cost more than a new bearing and circlip anyway (to get your later type in).volvo300 wrote: How do I get the axles out without breaking the new bearings installed in the housing?

Can I just tap the axles out???

BTW, thanks for great pics and quick reply

Cheers.

Peter

You say you have 'brand new' parts but if someone has pushed in the axle (wheel flange) and clamped it up to the drive flange it won't come out without taking part of the bearing inner with it, but if they have just hand pushed it in or maybe even just tapped it in, it might come out again by light tapping, anything else will damage the bearing inner parts . Really they should not have done that without the brake back plate, and even dropping it on the wrong end without the drive flange could damage the bearing as there is nothing to hold it together strongly. As I already mentioned its a one time assembly thing. If its a recovered part someone has already damaged the bearing to remove the brake back plate (as the wheel flange/axle has to come out for that).

I say the bearing is damaged, but I'm not 100% sure, maybe the plastic parts just snap back into place or maybe they don't matter much, but it looks bad to me, feels like something is bending/braking when you press the axle out (like a bearing cage), needs a fair bit of force. What ever it is that holds the bearing inners together when it is on its own is destroyed. Unfortunately I have binned all the old bearings now so can't check.

Anyway you should be able to get the spacer out of the original housing by tapping out the remaining bearing shell. Now you have all the grease and plastic (if any) out, you could put the housing into an oven and heat it to about 180C. The aluminium housing will expand more than the steel bearing shell+spacer and it should come out easily. With my later type the new cold bearing just dropped into the hot housing on reassembly.

Sorry its a bit complicated, I guess you have difficulty understanding the different bearing, and I don't have the old type.