Page 1 of 1

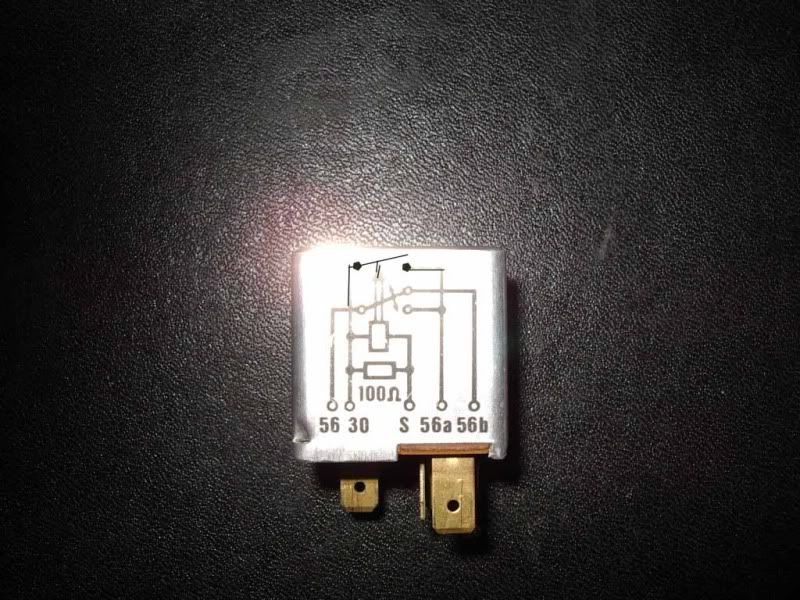

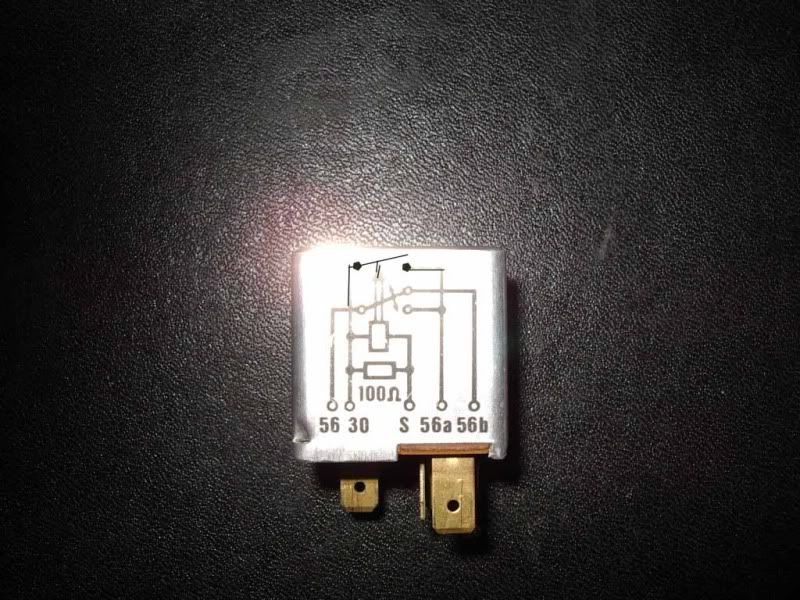

340 Headlight Relay

Posted: 07 Nov 2010 11:55 am

by autojohn

Hi, My headlight is staying on full beam as I try to dip, or flash them. Is there any way I could test the relay off car with a multi meter at all?

Re: 340 Headlight Relay

Posted: 07 Nov 2010 12:50 pm

by Malheus

Put a cable from plus to 30, minus to 86 or 87 i think

Then you hear if it click or not

Re: 340 Headlight Relay

Posted: 07 Nov 2010 01:34 pm

by autojohn

Thak you Mal' for your prompt reply. I'll keep you informed

Re: 340 Headlight Relay

Posted: 07 Nov 2010 02:11 pm

by autojohn

I did the test, though my relay numbers are quite different than those you suggested Mal, I put live to 30 and neg to S and the click sounded. Do you have any idea why the head lights won't flash or dip please.

Re: 340 Headlight Relay

Posted: 07 Nov 2010 06:58 pm

by autojohn

I now think the problem is with the switch because since I did the test with two wires Pos & Neg then returned the relay back to its holder, the main beam is now on dip; but it won't now click into main beam with the switch. I'll try and find time tomorrow to get at the switch. I'll keep you informed

Re: 340 Headlight Relay

Posted: 07 Nov 2010 08:22 pm

by volvodspec

yup, check if the brown groundwire is still connected, other than that it could be the mountingpieces that have broken off wich makes you pull the leaver towards you without actually operating the switch

Re: 340 Headlight Relay

Posted: 07 Nov 2010 08:43 pm

by L14MNP

Another vote here for broken stalk/mount.

Re: 340 Headlight Relay

Posted: 08 Nov 2010 11:16 am

by autojohn

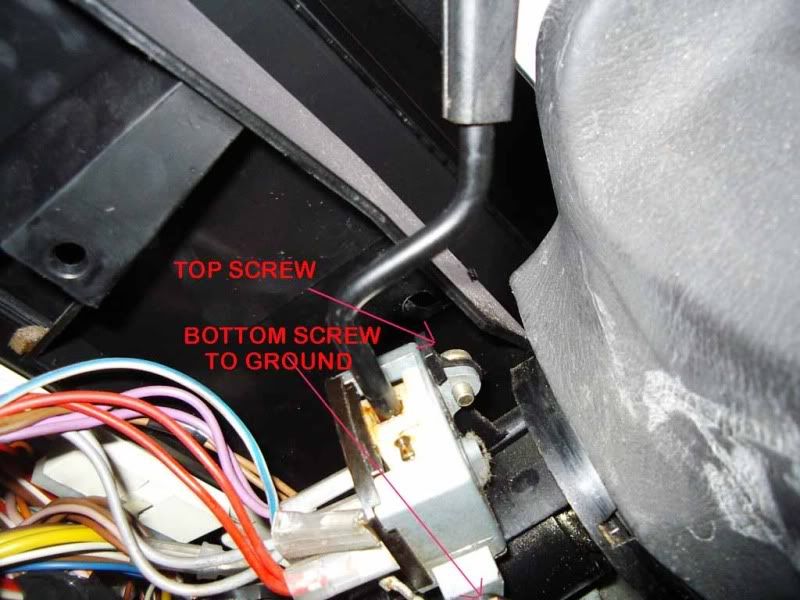

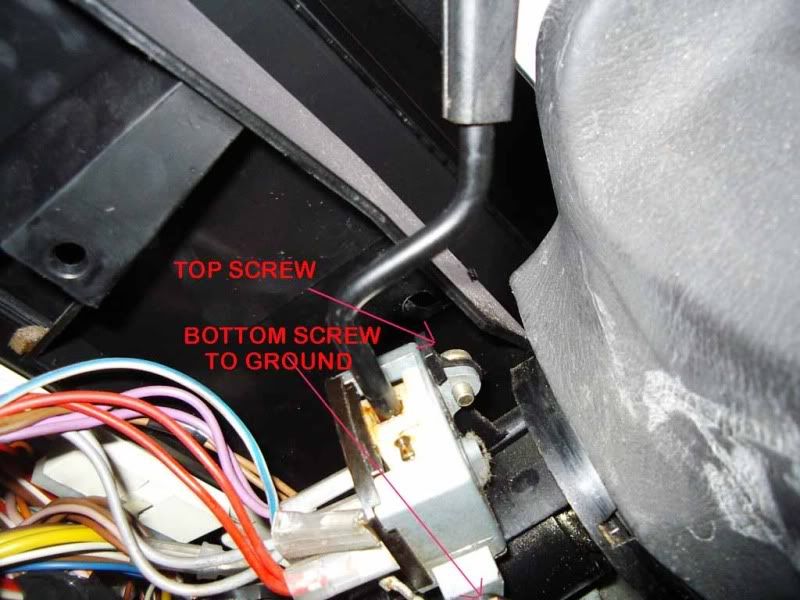

Ok Guys, it turns out to be the design of the `stalk` mount, you will see by the pictures that there are two screws to hold the stalk steady, but the problem is that these screws are a kind of swivel action in that if any one of them becomes loose then the switch/ stalk swivels as the arm is pulled towards the driver to flash or dip headlights

. The bottom screw is the one that acts as the `ground` anchorage, so it stands to reason that the contact to ground becomes U/S as in my case

This design also makes the Top screw impossible to get access to....I wonder how many guys have had this happen over the years ?

My modification was to drill a hole in the cluster facia so I could gain access the top screw. All tightened up and everything is back to normal with loctite applied to both screws

I also was able to apply some silicone grease to the nylon indicator `knock off` arm as an added precaution to future wear problems

Thank you all for your input on this over the last few daysl

Re: 340 Headlight Relay

Posted: 07 Dec 2010 11:32 pm

by theo2468

could of taken off your steering wheel instead.

theo

Re: 340 Headlight Relay

Posted: 08 Dec 2010 02:55 pm

by Ride_on

Yes the whole collar + switch unit slides off once you remove the steering wheel. There maybe a little plastic stud aswell.

The top bracket should stop the switch from rotating too much, usually what happens is the bottom screw hole breaks out because it is thinner on the left hand side. A metal plate with 2 holes in it provides an robust repair.

A general tip is to use fingers to control the stalks rather than hands. My mate went through a few collars and I noticed he used his hand quite often on the stalks, when I only use my fingers. Sometime the top one goes aswell.

Here's one I repaired.