B14, B172, B19/200, D16 engine, ignition, cooling, fuel & exhaust system, gearbox, variomatic, final drive... | Tuning: engine swaps, welded diff, clutch upgrades...

NO parts requests here, please use our V3M BUY & SELL corner

-

Pappa

- *** V3M DONOR ***

- Posts: 114

- Joined: 29 Dec 2007 11:58 pm

Post

by Pappa » 23 Apr 2008 09:17 pm

Hi. I am currently reassembling my Weber 32 DIR after cleaning and replacing parts and o-rings inside it, however I have encountered a problem - I cannot understand how the choke linkage system works, especially the part with the membrane and rod.

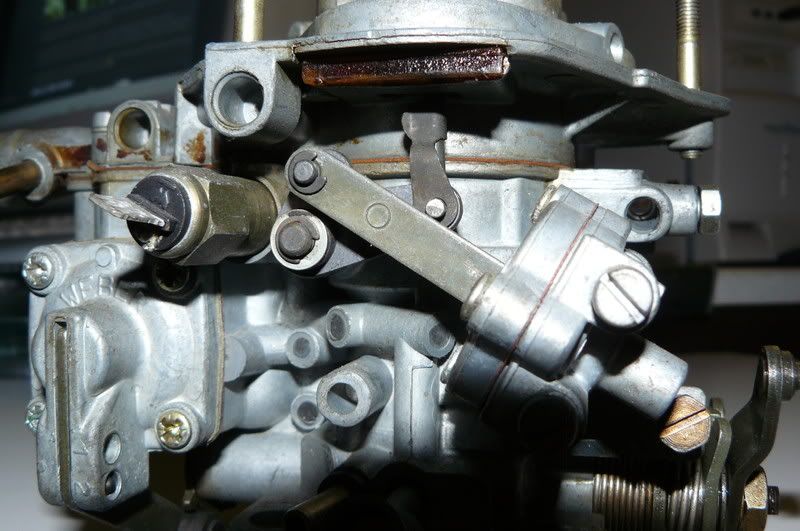

Here's how it is right now:

Everything just in pieces. As far as i have understood: choke engaged, membrane is free. Choke disengaged, membrane is pressed against surface.

But i just cannot seem to make this happen or put the connecting rod together with the membrane linkage correctly (just falls off or is impossible to fit properly). It might be possible that I've lost a part somewhere but everything on the drawing in the green book seems to be tthere.

If anyone has a pic or some tips please help. I have been screwing around with this for hours and I am just about to rip my hair off from the frustration

-

mac

- Posts: 1403

- Joined: 19 Apr 2006 11:02 am

- Location: Needham Market U.K.

Post

by mac » 24 Apr 2008 01:58 pm

Hi Pappa,

As with everything - it's easy when you know how!

The device you describe is the vacuum operated, choke flap, pull off diaphram. It sources vacuum from the primary choke venturi and serves to open the choke flap a little from closed during high depression conditions in the venturi - it prevents gross overfuelling during the full choke phase of warm up.

Your pic is a leetle fuzzy but the pull off pivot is certainly misplaced and the pull off rod is disconnected and the retaining clip probably missing.

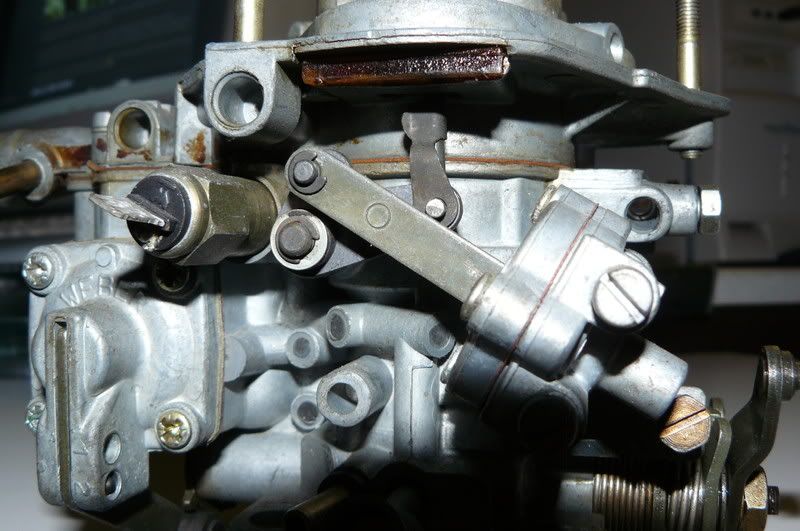

The pic. below shows the correct "choke off" configuration.

In this pic., with the choke fully on you can see the pull off rod ready to open the choke when sufficient vacuum appears in the diaphram chamber.

A final close up of the mechanism.

Don't be confused by thinking the mechanism pulls the choke flap on - it's quite the reverse.

Hope the above helps - Mac.

-

Pappa

- *** V3M DONOR ***

- Posts: 114

- Joined: 29 Dec 2007 11:58 pm

Post

by Pappa » 24 Apr 2008 03:17 pm

Thanks i get it now! I had a feeling the membrane was pulled in by vaccum but i thought that would be a little too advanced - guess not though

Thanks for the pictures, they explain everything and i do have all the parts

Btw, the choke linkage on the other side, the one with the spring - is this spring supposed to pull the choke arm back when you release the mechanism, or is it just a placeholder? Mine just sort of pulls it back, not fully, but i figure the choke wire will pull this back and forth.

Also thanks for the explanation on changing the clutch earlier. I printed your instructions on a small piece of paper and brought it out with me, and they explained pretty much everything i needed to know and it went smooth even for a monkey like me. If you ever find yourself in Norway let me know - i owe you quite a few beers

-

mac

- Posts: 1403

- Joined: 19 Apr 2006 11:02 am

- Location: Needham Market U.K.

Post

by mac » 24 Apr 2008 04:00 pm

Hi again Pappa, I'm glad to have been of help.

As for the choke operating rod on the other side of the carb body:- Pulling the choke cable moves the choke flap, by the connecting block (square swiveling block on the other end of the cable operating arm), acting on the spring on the rod you refer to. The cupped tube over the spring acts on the cranked shape of the rod which opens the choke flap via a linkage attached to the flap spindle. The lower end of the operating rod can move freely downwards through the square connecting block (it operates the choke flap as the force of the spring is greater than the force needed to close the flap).

When the choke cable is pushed in the square block moves down and physically pulls the choke flap open (the operating rod being at the limit of it's upper travel it cannot move freely through the block.

when the choke is fully on it can be influenced by the pull off diaphram (ie opened slightly) but to do this, any movement must be accomodated within the actual choke operating rod - the spring arrangement allows this. (when the pull off mechanism "operates" the choke from the other side the operating rod is moved downward against spring pressure (allowing the rod to pass through the square block) even though the choke cable is fully "out" and the choke fully "on".

The best way to understand this is to put the choke fully on and manually operate the pull off linkage - if you watch the spring arrangement on the other side whilst you do this you will see the spring compress and the rod move downward without influencing the position of the choke control cable.

The previously described pull off mechanism and the spring arrangement in the operating rod work together.

I hope this makes some sort of sense, but if not just ask again.

All the best - Mac.

-

Pappa

- *** V3M DONOR ***

- Posts: 114

- Joined: 29 Dec 2007 11:58 pm

Post

by Pappa » 24 Apr 2008 04:07 pm

Hi! Okay i understand it more now

But what i was thinking about is #28 on this photo:

My choke mechanism does seem to work okay i was just wondering if this spring is supposed to pull the choke flaps open again when i release the lever in the closed position. It does pull it back slightly if i close the choke flaps all the way in.

Thanks.

-

mac

- Posts: 1403

- Joined: 19 Apr 2006 11:02 am

- Location: Needham Market U.K.

Post

by mac » 24 Apr 2008 04:26 pm

Ah! - Mac was talking about the wrong spring!

The "primary" method of operating the choke is the choke cable which on the 340 is a solid wire and therefore will operate the system independant of the spring (you specify on your diagram). However the spring should be quite capable of opening the choke flaps fully on its own. In fact in cars which have a flexible choke cable, such a cable would not be capable of "pushing" the linkage into the off position.

In such cases the subject spring is the "primary" method of returning the choke flap/s to the open condition.

On your car (with no choke cable connected) fully close the choke flap by operating the linkage by hand - release - and the flap should open fully immediately. If as you suggest this does not happen it would seem that either a partial seizure is present or the return spring is not correctly fitted. If so the system would still work - but only by virtue of having a solid operating cable. (the fault would however still be present).

Mac.

-

Pappa

- *** V3M DONOR ***

- Posts: 114

- Joined: 29 Dec 2007 11:58 pm

Post

by Pappa » 24 Apr 2008 04:32 pm

Okay thanks. Mine is not capable of fully opening the choke flaps and i think the spring is fitted correctly (can't think of any other way to fit it) so i guess it's just a little worn after many years. It'll still work though i guess, so I'll just leave it.

Thanks for all your help, now going to cut out new gaskets for the carb then it's time to fit it back on the engine and test

Would you recommend fitting a new fuel filter before i fire it up first time round? I do have one laying around.. seems like a good idea to ensure the newly-cleaned carb won't be stuffed with junk in a matter of seconds

-

mac

- Posts: 1403

- Joined: 19 Apr 2006 11:02 am

- Location: Needham Market U.K.

Post

by mac » 24 Apr 2008 04:36 pm

New fuel filter is never a bad idea.

Good luck

Mac.

-

Pappa

- *** V3M DONOR ***

- Posts: 114

- Joined: 29 Dec 2007 11:58 pm

Post

by Pappa » 24 Apr 2008 08:26 pm

Hi again. I've refitted the carb and the car idles just about how it idled before I cleaned the carb, except for two noteworthy exceptions.

Now the car doesn't die on full choke with no throttle applied. This is because the mechanism that opens the throttle valve was adjusted wrong so the throttle valve wasn't opened at all at full choke i guess.

Second the car seemed to stabilize at 900 RPM faster than before, but it could be only this one time. Before it stabilizes at 900 it's around 500-700 and it shakes pretty bad.

The shaky engine problem is still present though, along with cylinder #3 not igniting properly at idle. I'll fit an exhaust system tomorrow and see how it goes.. no expectations though. I am almost positive I've got an air leak somewhere i just cannot seem to find it.

But i _do_ suspect the hose from the carb to the renix as the car revs up when i spray "start gas" in this area. I am also worried i didn't tighten one of the bolts on the carb hard enough because i had to grind the wrench down quite a bit in order to screw the nuts closest to the engine side down, and when tightening the last of the bolts the wrench would start coming apart so it slipped off the nut. I still think i tightened it pretty good though and I put loctite on the bolts so i think they're good.

I hope it's just the renix hose