Page 2 of 2

Re: 300 Wheel Bearings

Posted: 18 Oct 2010 01:48 am

by Ride_on

volvo300 wrote:

How do I get the axles out without breaking the new bearings installed in the housing?

Can I just tap the axles out???

BTW, thanks for great pics and quick reply

Cheers.

Peter

No this is what I am saying, on the later bearing you cannot remove the wheel flange/axle without damaging the bearing, its only held together by bits of plastic inside and the insertion force is much higher after it is clamped together by the drive flange and the big nut. The wheel flange and drive flange hold the inner parts of the bearing together strongly and the axle is tapered into the bearing inner and gets stuck (oddly the drive flange side is not tapered). There maybe a special Volvo tool that allows to be separated it but its not clear, likely it will cost more than a new bearing and circlip anyway (to get your later type in).

You say you have 'brand new' parts but if someone has pushed in the axle (wheel flange) and clamped it up to the drive flange it won't come out without taking part of the bearing inner with it, but if they have just hand pushed it in or maybe even just tapped it in, it might come out again by light tapping, anything else will damage the bearing inner parts . Really they should not have done that without the brake back plate, and even dropping it on the wrong end without the drive flange could damage the bearing as there is nothing to hold it together strongly. As I already mentioned its a one time assembly thing. If its a recovered part someone has already damaged the bearing to remove the brake back plate (as the wheel flange/axle has to come out for that).

I say the bearing is damaged, but I'm not 100% sure, maybe the plastic parts just snap back into place or maybe they don't matter much, but it looks bad to me, feels like something is bending/braking when you press the axle out (like a bearing cage), needs a fair bit of force. What ever it is that holds the bearing inners together when it is on its own is destroyed. Unfortunately I have binned all the old bearings now so can't check.

Anyway you should be able to get the spacer out of the original housing by tapping out the remaining bearing shell. Now you have all the grease and plastic (if any) out, you could put the housing into an oven and heat it to about 180C. The aluminium housing will expand more than the steel bearing shell+spacer and it should come out easily. With my later type the new cold bearing just dropped into the hot housing on reassembly.

Sorry its a bit complicated, I guess you have difficulty understanding the different bearing, and I don't have the old type.

Re: 300 Wheel Bearings

Posted: 18 Oct 2010 03:14 pm

by trabitom99

Ride_on wrote:volvodspec wrote:you wish

hammering the broken one out might work, but there isn't enough space to get the new one in.

best way to get it out is to remove the hub shaft, that involves the setup on the pic above yours, including a torch...

In other words you may need to replace the bearing in order to fix the stud. The manual says something about using Volvo tool 5433 and 5434 to remove the 'bearing cup from the drive flange', but it has already stated how to remove the drive flange, I think it might mean the wheel flange, and so you might be able to remove the inner part of the bearing and not damage the bearing when disassembling using this, instead of my method above of grind cutting off the stuck on part and replacing the bearing. Study the diagrams above to confirm what I mean by the drive flange and wheel flange.

Oh dear

Thanks to you both for the info ...

Tom

Re: 300 Wheel Bearings

Posted: 18 Oct 2010 04:29 pm

by trabitom99

volvo300 wrote:The bearing housing comes of a 1981 Volvo 343 DLS (B19A).

I suspect it's similar to the one in my R-sport (343-GLS).

I'll see what I can do the that 'collar'... I think it's the one Haynes is calling 'spacer'.

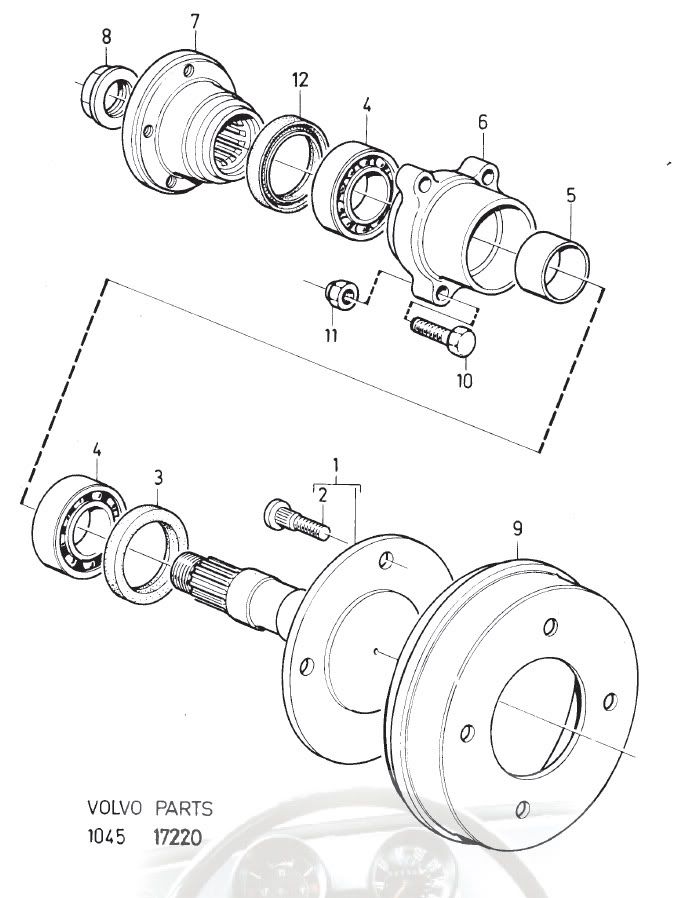

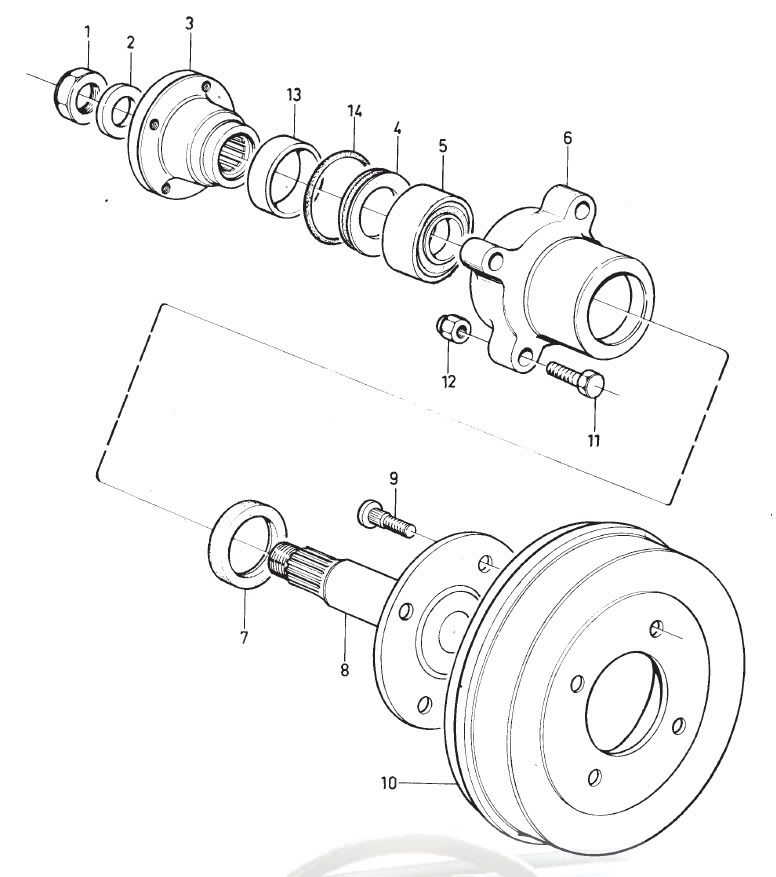

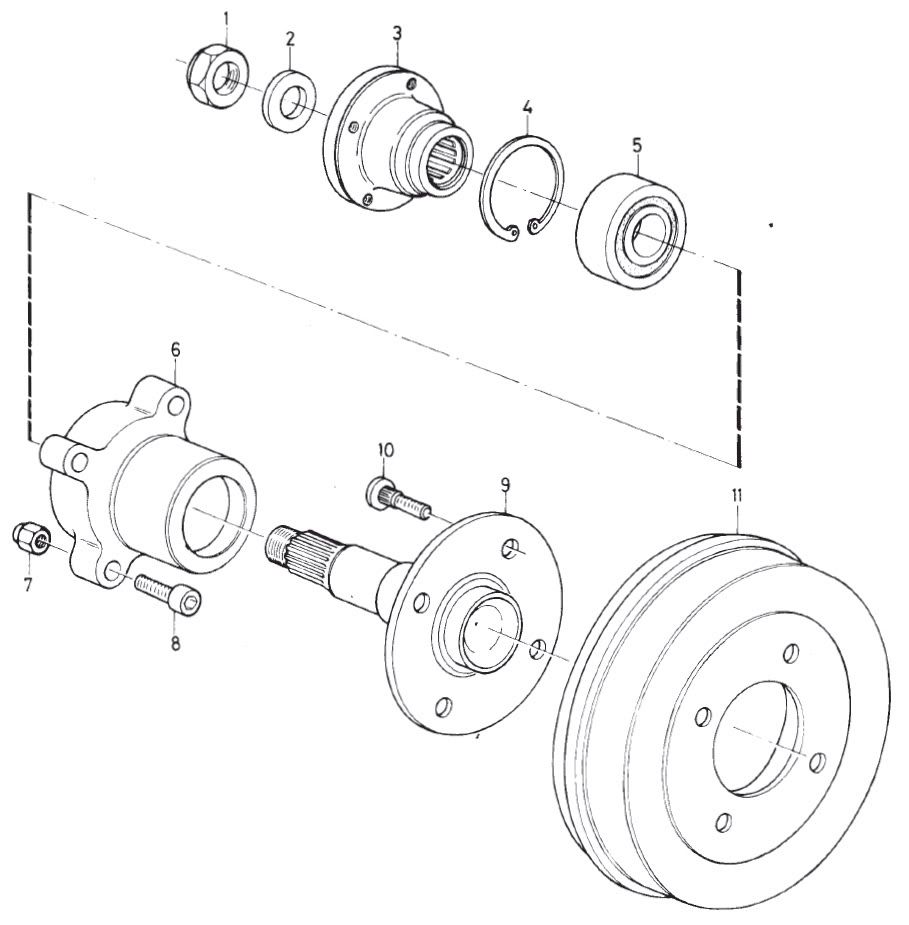

Here are the pics from the green book if that's any extra help:

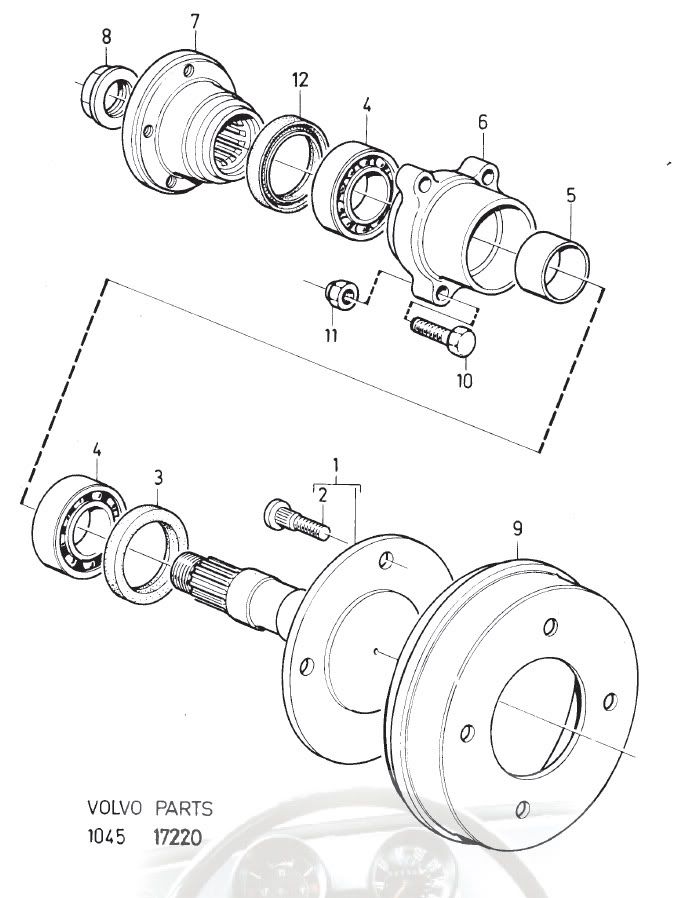

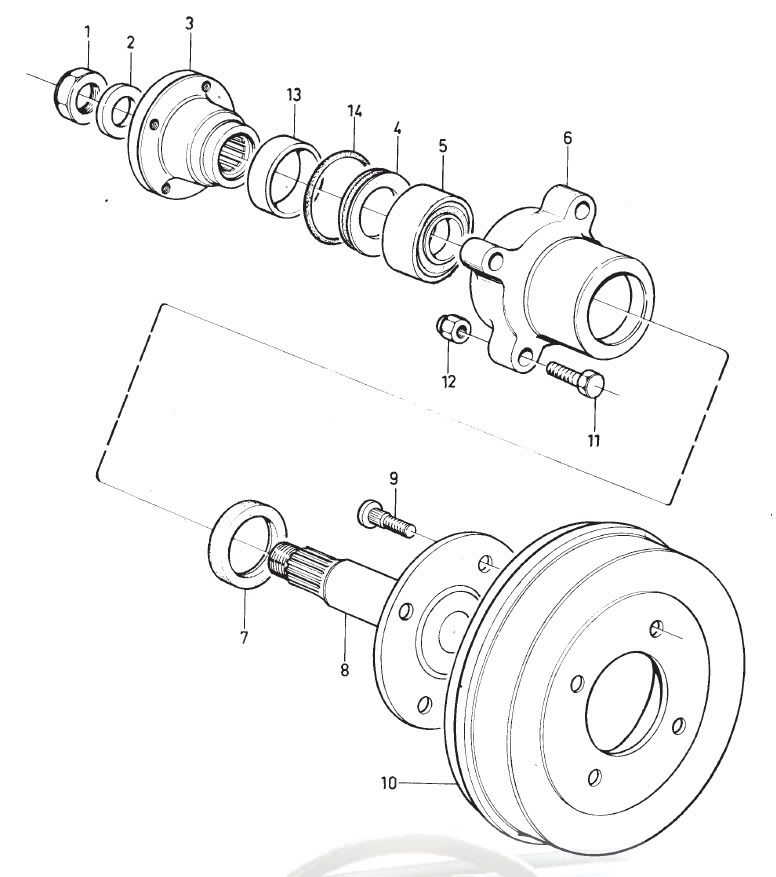

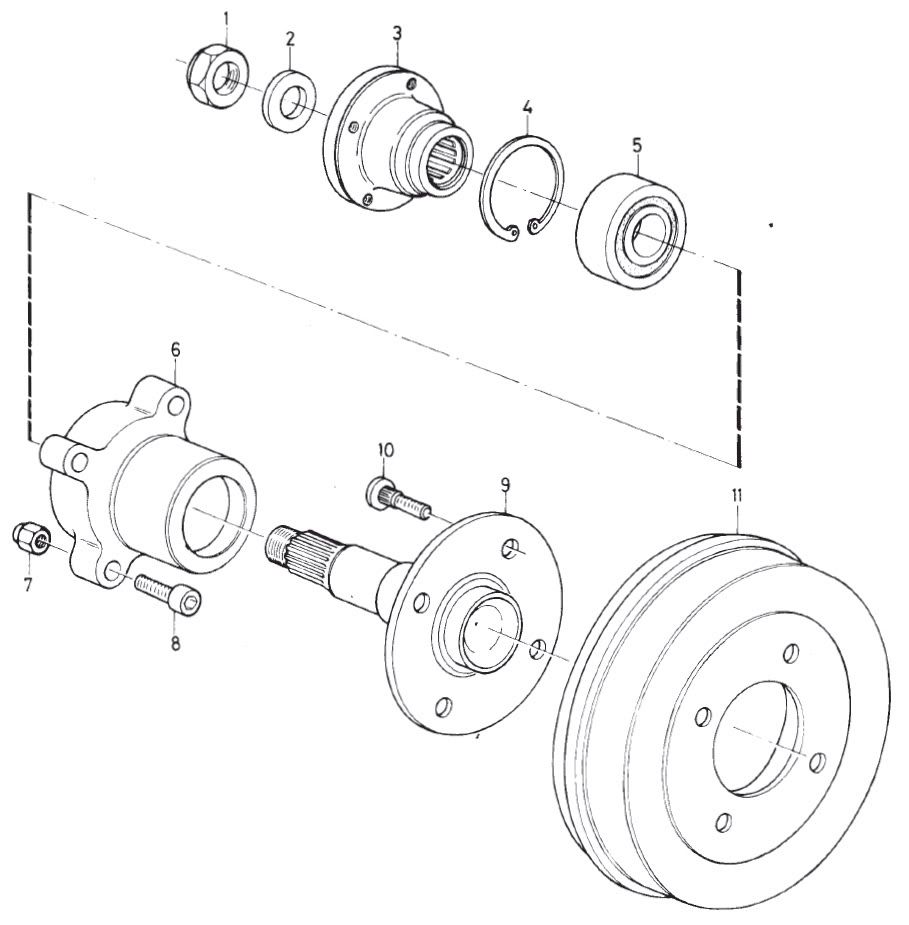

340 chassisno <120999:

360 chassisno <120999:

all versions chassisno >121000:

Cheers

Tom

Re: 300 Wheel Bearings

Posted: 18 Oct 2010 07:43 pm

by volvo300

Hi ride_on.

That do make sense!....

I'll take a pic of the new ones that I have laying around somewhere.

A guy sold these two for about 20£ a while ago, and I was quick

I will try baking the old bearing housing and see if the parts will loosen.... After 30 years of marriage they will not come apart without struggle

I'll upload some pics later tonight / tomorrow.

.... and Hi Tom.

Thanks for the pics

Have a nice evening.

Re: 300 Wheel Bearings

Posted: 19 Oct 2010 08:48 pm

by volvo300

Hi all.

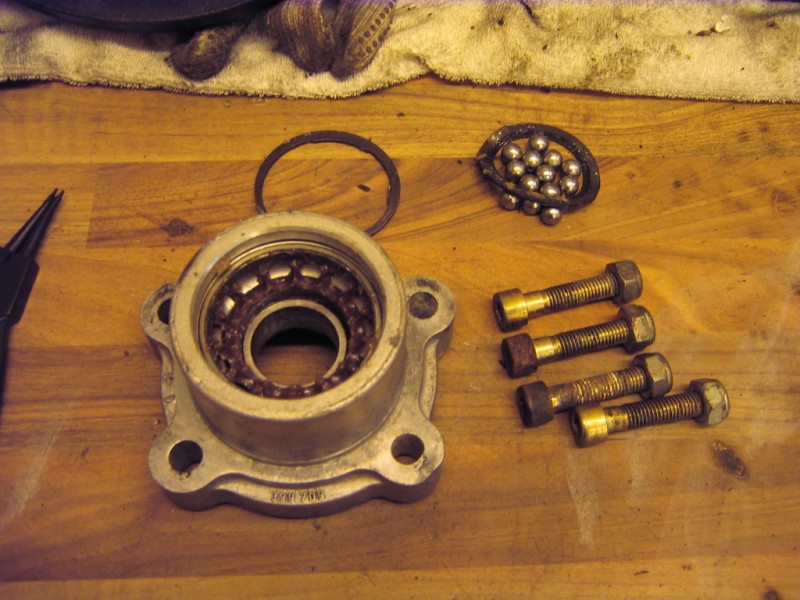

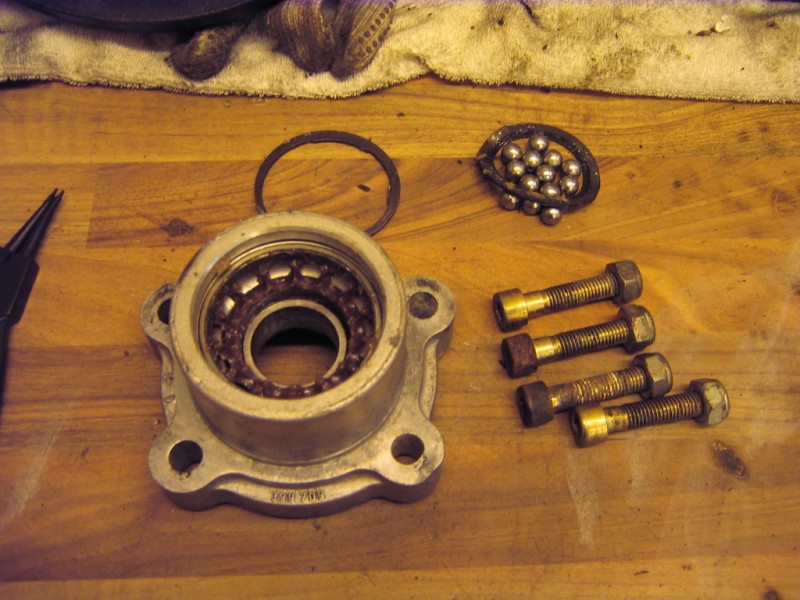

Here's the pics of my old and new bearing housing.

I have followed the directions from ride_on and given the housings some heat.

New bearing housing with a 'new' bearing hammered to pieces

New housing with the rest of the bearing inside... ready for heating

Old bearing housing heated for about 35 min. and ready for removal of collar.

Collar in old bearing housing.

How to remove the collar after heating.

Collar removed.... old and rusty.

Collar from old bearing.

Old housing without collar... The rest of the old bearing needs to be removed.

Old housing (left) and new housing (right).

Old housing (left) and new housing (right).

Old housing (left) and new housing (right).

Now I have 2 choices.

Install the old housing with a new bearing... The old bearing is hard to find

Install the new housing with a new type bearing.... offcourse with the new style axle and brake plate.

Which one is the best???

Does anyone have a method to install the axle without damaging the bearing??

Cheers.

Peter

Re: 300 Wheel Bearings

Posted: 20 Oct 2010 02:24 pm

by Ride_on

That's good going. I see the manual mentions about 'not using excessive force', I guess it might be possible to damage the inner on the drive flange side if it catches or there is alot of friction. I havn't done that part yet, but I had hoped minimal tapping would be enough to get it in to get the drive flange nut on, which will then 'push' only against both side bearing inners. Also of course you never want to 'hammer' bearing surfaces together.

The perfect way would be to tap axleshaft in while supporting the bearing inner on the drive flange side until you get enough thread through to use the nut. You could also use the drive flange +nut itself for partial assembly, and maybe take it off again for installation to the De Dion axle. Or try to install the Axleshaft after assembling to the De Dion Axle.

Basically you want to assemble by only 'compressing' the bearing inner together.

I say it would be better to use the later housing, less parts. As a final touch you might want paint the housing as it tends to suffer galvanic corrosion against the steel parts (mostly not the bearing though). I have painted the jointing surfaces of the housing with thin coats on all sides. Although this part seems to last ok as its thick, the aluminium gearbox mounts completely fall apart. Even a bit of primer seems to help alot.

Re: 300 Wheel Bearings

Posted: 20 Oct 2010 02:36 pm

by Ride_on

Actually, just had an idea, knock the inner out from the old bearing and use it as a support to tap shaft in (the splined part of the axle is narrower than the inner). Not all the way, just enough to get the nut or drive flange on and use it for further clamping up.

Re: 300 Wheel Bearings

Posted: 20 Oct 2010 09:36 pm

by volvo300

Hi again ride_on.

After I looked at the housings once again, I found that I can't use the new style housing

The thing is, that the old style De Dion axle has a smaller hole than the newer style De Dion !!!!

I have to use the old stye housing, and live with all the parts that follows....

Too bad, but I will install a GLT suspension on my R-sport later (propably in a few years)....

well, I'll try to use the trick you gave.

I'll keep you updated, but I won't be able to do this job for a few months, so have patience..

Cheers

Peter

Re: 300 Wheel Bearings

Posted: 24 Apr 2014 11:59 am

by Number 47

I have just done both my rear bearings. Mine are the ones with the spacer. They were full of crud and in a sorry state. I followed the removal instructions from the haynes manual, kind of. They recommend driving them out with a drift. I didn't have a drift so I used a socket.

I first cleaned as much of the crud as possible from the spacer where it meets the housing with a small probe. I then sprayed a good bit of penetrating fluid in the gap and left it for an hour. I used a 32mm socket on the inner race as it was the largest I had. A lump hammer with the housing across the top of my open vice jaws. Took a bit of lumping but the lot came out easily enough.

Gave the housing a clean then popped the bearings in a plastic bag and into the freezer and went to bed.

This morning I popped the housings in the oven at 200c for 20 minutes and the bearings from the freezer just dropped straight in.I had the old bearing on hand in-case it needed a tap but it was not required. Popped them outside to cool down. Eh voila!

All in all, easy enough and pretty painless, just make sure the wife is out before using the oven!