Page 21 of 27

Re: Turbo 360: Doin' it right.

Posted: 23 Nov 2011 01:24 am

by foggyjames

Was it Tony's car? Not that many people have had the sills off. It's so annoying that the outer skin is clean...but there's nothing to be done about it.

Yeah, just take it easy with the heat (i.e. once tacked, do it slowly, in short sections), and you shouldn't have too much trouble with deformation.

I was thinking that about the waxoyl

cheers

James

Re: Turbo 360: Doin' it right.

Posted: 24 Nov 2011 06:59 pm

by Ride_on

Yes probably my car under the dreaded rust title. Those inner sections look almost new!

Have killed 1 cheap grinder myself while cutting out the inner wings fron Marks car! 1 Stolen, have a fairly good Bosch that is lasting well to cut derust and grind welds on an old 360.

The rust between spotted panels is the killer, can't be removed any other way than depaneling. Think this is going to become more common as cars get older. Get used to it! Also once you start the strive for perfection becomes infectious, but you've started with a mostly solid car.

Re: Turbo 360: Doin' it right.

Posted: 24 Nov 2011 11:52 pm

by L14MNP

Agreed.

Check the Nova link in one of my previous posts for a good spot (see what I did there?

) of depaneling mate!

Mark came over to help with cutting the shell/sill for fit, and through nobodies fault, we fucked it up a bit.

There is less space to work on this side, and the panel is bent all over the place due to being stored for about ten years.

Whoops...

[Uncool and slightly annoying internet word] Meh. [/Uncool and slightly annoying internet word] it's not like it doesn't need welding elsewhere!

Still looks OK here.

What's the score with these, are they both for the B19 airbox?

I have removed them, as iirc they were surplus to requirement. The one on the leg is mig welded on as standard. :/

I hope to start filling some more holes this weekend, time pending. Gotta get this moving along! I plan to book it in for the cage in Jan/Feb.

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 12:00 am

by Speedy88

Oopla, get the filler out

So are you just going to put in some metal from behind or weld an extra section on the outside? I've often wondered the "right" way of going around this. I usually just keep welding until there's no more holes

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 12:06 am

by L14MNP

Speedy88 wrote:Oopla, get the filler out

So are you just going to put in some metal from behind or weld an extra section on the outside? I've often wondered the "right" way of going around this. I usually just keep welding until there's no more holes

Filler.

I will weld in a fillet(?) section flush with the quarter/sill dude. It needs a strip puddle welded to the inside of the quarter and sill anyway to add strength. At least I think that's why people do that. Makes sense, plus it makes it easier to weld in the anti-ballsup repair section.

As for the 'proper' way, imo that's as little filler as possible! I'll see what I can acheive with the metal glue machine before I bust out the plastic padding!

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 12:37 am

by volvosneverdie

Arch gaps, exit stage left.

Enter, sill gaps.

Its the new craze....

Dang man.

At least you'll be filling it with good metal though eh?

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 12:55 am

by L14MNP

Might just kick it off the spit and stove the roof in with the nearest blunt object.

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 01:20 am

by volvosneverdie

Don't do that man. It's had one million man hours.

And its only six month to summer.

Might as well finish it off.

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 01:28 am

by L14MNP

volvosneverdie wrote:Don't do that man. It's had one million man hours.

And its only six month to summer.

Might as well finish it off.

Joke fail.

Remove 0.75 million of those hours, as I don't think watching The Big Bang Theory in the garage counts.

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 01:33 am

by foggyjames

Ouch. Can you use part of what you cut off? I've found that the Swedish (or Belgian!) steel > Dutch steel > British steel. I usually keep a 7/900 or 850 panel kicking around as a source of quality steel for little bits like this.

cheers

James

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 01:36 am

by L14MNP

foggyjames wrote:Ouch. Can you use part of what you cut off? I've found that the Swedish (or Belgian!) steel > Dutch steel > British steel. I usually keep a 7/900 or 850 panel kicking around as a source of quality steel for little bits like this.

cheers

James

I can indeed James, kept the very section that was cut out (and wished I could go back in time 2 minutes).

Yeah, seems decent steel. It has a fair bit of galvanised Nissan steel in it too, and I was gonna chop the roof skin off Johns 343 when I butcher it for a few sections tomorrow.

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 05:14 pm

by L14MNP

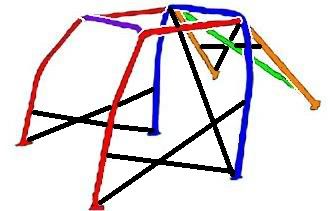

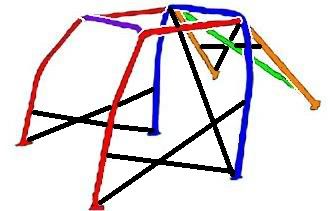

Went to see Stuart at AAS this afternoon, and after discussing a cage design we are both happy with, I have booked the car in for the end of January.

It is going to be a 6 point weld in built to MSA blue book specs, obviously tagged to the A and B pillars and with sill boxing, and as tight a fit as possible. I have attempted to show what I am going for in the below pic, which is originally a Pedersen Racing cage. Mine will obviously be scratch built.

I have added the black parts - as if you can't tell lol. The original crappy 'door bars' have been deleted. I am having the X's as shown, with the second bar as low as it can be at the front. I want a harness bar, so have to have a rear X instead of a single diagonal, and Stuart says that the diagonal from floor to roof is also essential.

I do like the look of the tunnel bracing on this (and that's it!), but AAS advise against it...

as if the car is in an impact, he reckons with the design we have basically agreed upon that it shouldn't be too terminal. With the tunnel bracing, he says it may do all kinds of damage.

I am of the opinion that if you bend a car with a weld in cage that it is never gonna be pretty anyway.

As cool as (I think) the tunnel bracking looks, I will not have the harness bar as it is in the second image (too close to seats), so it may not look 'right' even if I do go for it. I have no doubt it would be advantageous in removing a lot of flex though.

What do we think?

The place I have chosen to make the cage don't mess about, and know what they're talking about. I wouldn't use them otherwise!

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 05:35 pm

by volvosneverdie

Limp wrote:What do we think? The place I have chosen to make the cage don't mess about, and know what they're talking about. I wouldn't use them otherwise!

Spoke to a few people about these when I was pondering a SS exhaust system for a Chavleer aaaages ago.

The word on the street was that they were indeed an awesome firm. Not cheap, but you get what you pay for eh?

Cage looks complicated and impressive man.

I take it you shall be removing the pussy seat then.

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 05:38 pm

by macplaxton

We think the post needs a bit of repetition editing out. Been on the sauce? :s

Re: Turbo 360: Doin' it right.

Posted: 25 Nov 2011 05:44 pm

by L14MNP

macplaxton wrote:We think the post needs a bit of repetition editing out. Been on the sauce? :s

I dropped the ball

I copied the entire post before I previewed it, then attempted to add an image, it didn't paste, the whole post did. I thought I had removed all that was unrequired, guess I never scrolled far enough down! Sorted now.

Aye Ben (lol @ PNG stylee moniker), they're the business. I know a few lads that have had exhausts made there, and I have seen a few of their cages. I would have had a SS exhaust by them, but the waiting list was crazy - so I went to Powerflow...

It will have two seats.