Page 6 of 9

Re: Damn that blower gone again.

Posted: 16 Jul 2013 04:51 pm

by mac

Just a quick update,

Having initially seemed very helpful, I sent Otter Controls (the maker of the thermal cut out) my test data as to temperature and current drawn through the heater resistor packs.

They pointed out that as the switches were uncased the spec.number printed on the case was no longer available and I would need to determine the point at which the switches tripped. (load current not temperature).

I duly sourced new resistor packs and built a test rig including a variable load - and ascertained the data required.

I also supplied photographs of cased (early type) switched with the identifying numbers clearly visible.

Eventually, after some prompting I have received a reply merely referring to their original mail - ie they are not "able" to assist in any way. My test data is it appears insufficient, and the identifying numbers no longer seem to identify anything.

I have to conclude that they are simply not interested in offering any advice or assistance to potential customers (despite suggestions on their website to the contrary) if their involvement does not result in a multi thousand pound order. I may be doing them a disservice but this seems potential short termism worthy of a politician.

Considering the amount of work put in this "helpfulness" leaves me a little irritated - especially as G6 switches are nor produced to a standard range, but to order.

I shall now peruse other avenues!!!

Mac (quite grumpy really).

Re: Damn that blower gone again.

Posted: 16 Jul 2013 07:54 pm

by V6 Man

So all the waffle about "yes, we'll be able to source the original specifications and supply you with some matching ones" was just that; waffle?

Re: Damn that blower gone again.

Posted: 25 Aug 2013 01:41 pm

by mac

UPDATE

I haven't forgotten My resistor project - in fact a fair bit of progress has been made.

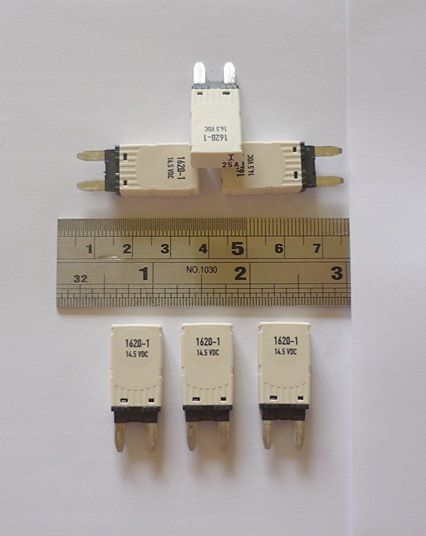

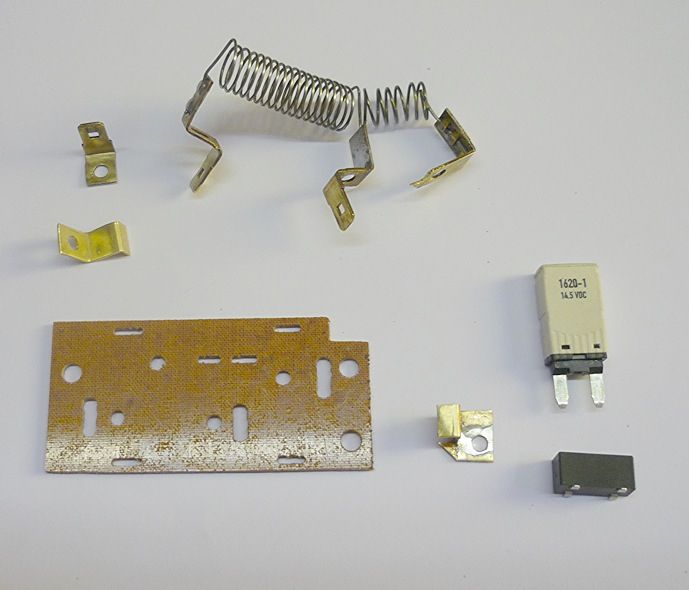

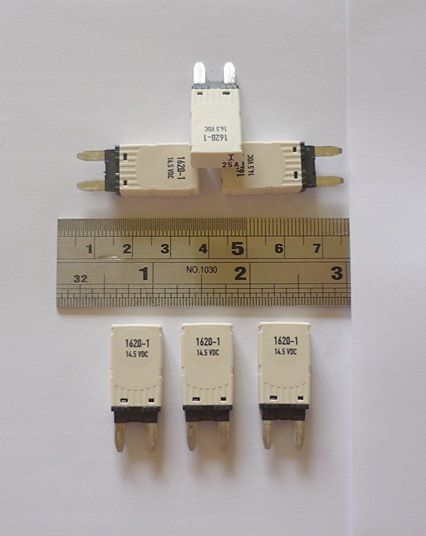

After the disappointment of the OE suppliers negative attitudes I contacted a company (ETA) in the USA who was most accommodating - the result was a delivery of samples foc for me to play with -

These cut outs have std. minifuse tags and I have sourced suitable sockets (also from a co. in the States).

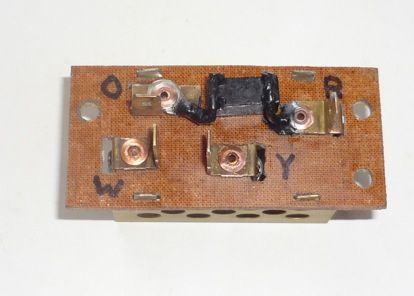

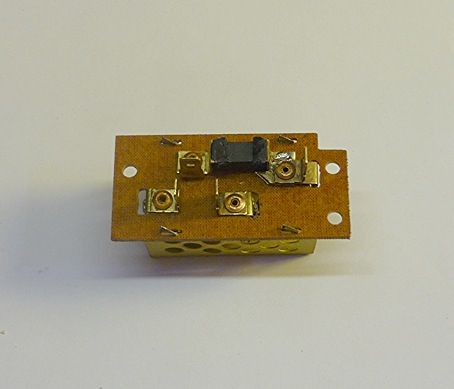

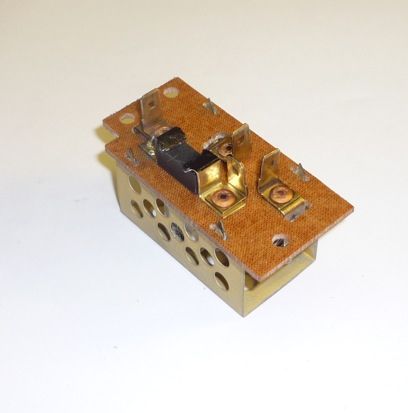

The new thermal cut out from ETA with a mounting socket from Keystone, via Digikey.

"on paper" these should work and initial trials on my test rig are very promising - they perform very similar to a new OE resistor pack.

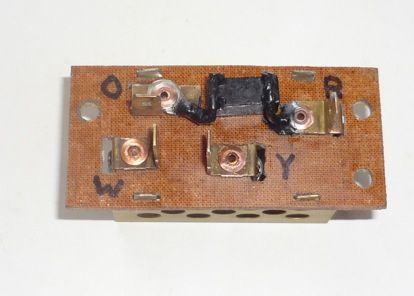

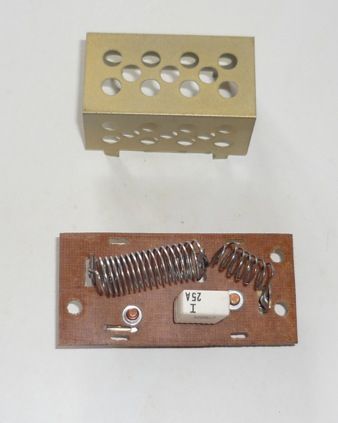

My latest trial method of mounting socket - solid wire tails (actually conductors from 10mm T&E.

The cut out plugs full depth into the socket, is a good tight fit, and cannot come out due to the perforated guard.

Found a decent flux - resistive wire crimp mounts re- made with solder.

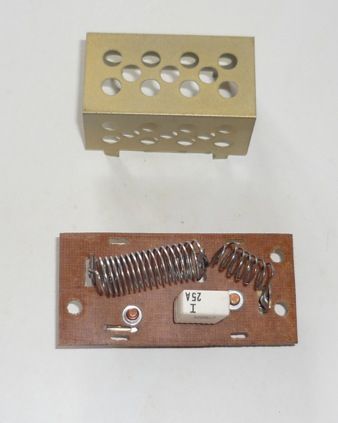

I've had to reposition components slightly which has needed a new board design to accept the new cutout and socket. I've hand made a few from 2mm "Tufnol" Whale (see above) but if the design works out I'll mill batches on the XY table on the micro mill.

I've built 3 versions of which the above seems favourite at present. All three have run at full speed using my " high current" motor for lengthy periods.

Trying them with my Art Deco death ray and simulating high under bonnet temperatures gives a performance nigh on identical to the "new" and working packs I have tried.

Production of new boards

Next step is on-car trial - one has been sent to my guinea pig and results will be evaluated in due course. In the meantime if anybody else has a failed unit on an 86 on car feel free to send it to me - I'll be happy to refurb it as another test subject.

Mac

Sent from my iPad

Re: Damn that blower gone again.

Posted: 25 Aug 2013 02:17 pm

by Chris_C

You know my thoughts on this already Mac, but I'm really pleased how this is turning out

Out of interest, are there ever any temps generated in the pack that might scare soft solder? (I take it it is soft soldered?)

Re: Damn that blower gone again.

Posted: 25 Aug 2013 02:42 pm

by mac

Yep! soft solder, Ersine multi core, MP around 188c

Highest stabilised temp seem in testing was 162c - with no cooling air flow and "high" current motor.

Under normal running, temp peaks at 61c.

The mechanical crimp fitting of the resistive wire has been retained but merely encased in solder.

Unlikely there'll be an issue.............he said

Mac.

Re: Damn that blower gone again.

Posted: 25 Aug 2013 05:29 pm

by Chris_C

Cool

Re: Damn that blower gone again.

Posted: 26 Aug 2013 03:19 pm

by mac

Just a bit more done -

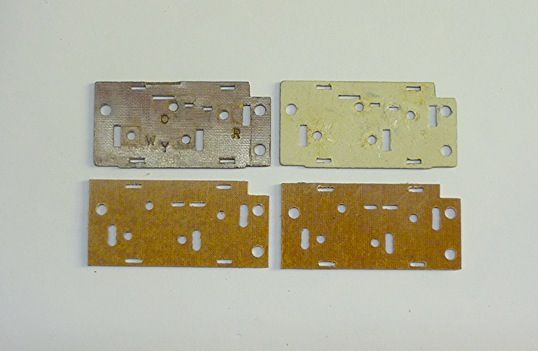

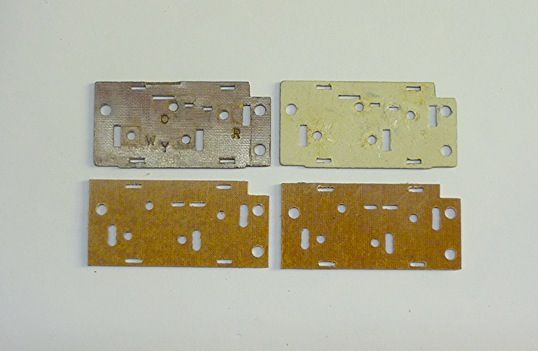

"Production" boards with two originals - notice the subtle redesign,

I'm still undecided as to the best method of connecting the cut out socket - the last effort was - inelegant - and I'm moving towards making my own "custom" terminal clips (from 0.7mm brass)

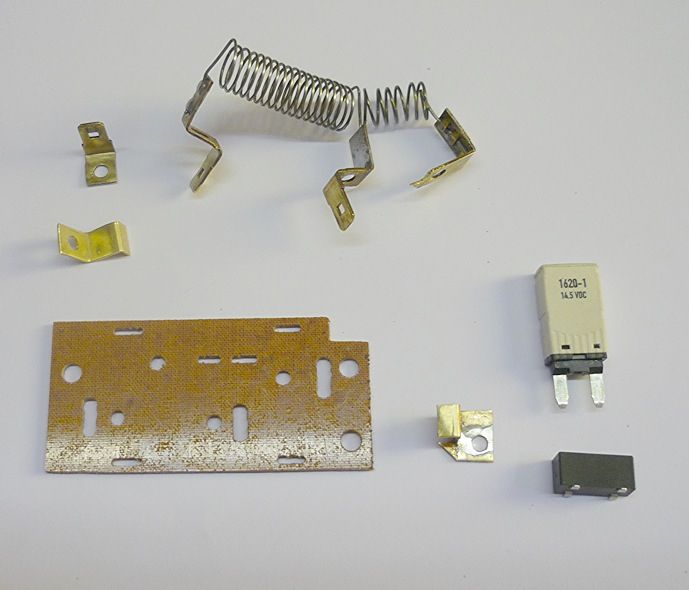

Components ready to assemble - with fabricated socket attachment clips

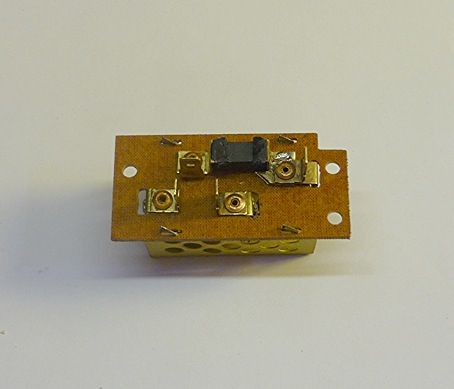

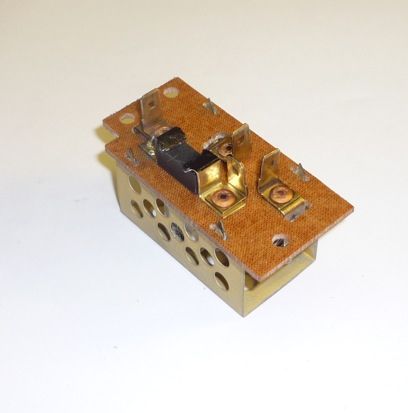

Two views of the assembled unit

This unit ran for another 30mins this afternoon.

All for now girls - Mac

Re: Damn that blower gone again.

Posted: 26 Aug 2013 10:09 pm

by Hell Driver

Fantastic work!

Re: Damn that blower gone again.

Posted: 27 Aug 2013 07:55 am

by Cliché Guevara

As muc as I appreciate the ammount of time effort and thought that is going into this project.

Have these cars ever caught fire from a failed thermal cut out or where the cut out has been bridged?

Re: Damn that blower gone again.

Posted: 27 Aug 2013 10:24 am

by mac

Not to my knowledge, and I've seen many failed and bridged cut outs.

For an ignition to take place (I know I'm being obvious) the heat source must exceed the combustion temperature of flammable material in the immediate area of the heat source. On test, with a stalled motor, the highest temp. I have actually seen was 162c (on my variable resistor rig - with a bridged cut out) - in real life, even with a bridge wire, much lower. As to fuel source - you have the cutout casing designed for automotive use (s.e.plastic) and the Tufnol board (n.f.).

In theory a cut out failed closed, a seized blower motor, supply fusing not to spec. and a handfull of petrol soaked dry leaves in the heater box (fan removed to allow debris to enter) could result in a fire - but not the most likely of scenarios - but of course anything is possible.

The possibility must have been considered at the OE design stage - which is one reason why I feel it important to stay as original as possible rather than just bung a handfull of resistors (or voltage drop diodes) into a box and give it a good shake!

I'm curious why you raise the subject - do you know of a case, or are you suggesting the possibility as a reason for not persuing the problem?

If you know of a case where fire resulted from a failed resistor pack I should be verrrry interested.

Mac.

Re: Damn that blower gone again.

Posted: 27 Aug 2013 12:11 pm

by Speedy88

As always, very nice work Mac!

Re: Damn that blower gone again.

Posted: 27 Aug 2013 01:38 pm

by 340GLT

These are looking great Mac. I dont know if you need one at all but i have a NOS mk2 unit?

Adam

Re: Damn that blower gone again.

Posted: 27 Aug 2013 01:52 pm

by mac

Thanks Adam,

Yes - most interested - PM me with your price (or possibility of borrowing if not for sale).

Mac.

Re: Damn that blower gone again.

Posted: 28 Aug 2013 06:34 am

by Cliché Guevara

mac wrote:Not to my knowledge, and I've seen many failed and bridged cut outs.

For an ignition to take place (I know I'm being obvious) the heat source must exceed the combustion temperature of flammable material in the immediate area of the heat source. On test, with a stalled motor, the highest temp. I have actually seen was 162c (on my variable resistor rig - with a bridged cut out) - in real life, even with a bridge wire, much lower. As to fuel source - you have the cutout casing designed for automotive use (s.e.plastic) and the Tufnol board (n.f.).

In theory a cut out failed closed, a seized blower motor, supply fusing not to spec. and a handfull of petrol soaked dry leaves in the heater box (fan removed to allow debris to enter) could result in a fire - but not the most likely of scenarios - but of course anything is possible.

The possibility must have been considered at the OE design stage - which is one reason why I feel it important to stay as original as possible rather than just bung a handfull of resistors (or voltage drop diodes) into a box and give it a good shake!

I'm curious why you raise the subject - do you know of a case, or are you suggesting the possibility as a reason for not persuing the problem?

If you know of a case where fire resulted from a failed resistor pack I should be verrrry interested.

Mac.

No I dont know of a case.But as you are persuing originality I'll keep my mouth zipped

My one has had the bimetal bridged and works fine (obviously) does the Mk2Golf unit have the thermal cut out on it?

As it was an OE thing could this be Volvo being ultra safe as usual and over engineering their system.

Re: Damn that blower gone again.

Posted: 28 Aug 2013 10:35 am

by mac

Firstly - no need to keep zipped - you're very welcome to add your views.

Mk2 Golf pack - don't know - how similar is it to the 300s ? Anybody know the answer to this ?

Over engineering - less of a tendency on the 300 (there are a number of marginal designs (wheel and strut bearing))

But still a valid point.

Mac.