Page 1 of 4

"Professionals" huh!

Posted: 25 Oct 2015 05:53 pm

by mac

Afternoon girls,

As a diversion to take my mind of carbs, carb - u - rettors ~~ drool! slavering, !! I've been looking at giving some assistance in changing the rear wheel bearings on a certain car (verry grumpy O/S).

The owner, whilst being more capable than he thinks, felt the task beyond him and had already allowed his local garage to attempt the repair.

Apparently they fiddled with the car for a whole day before giving up and pronouncing the job impossible.

Anyways I popped over a few days ago and dodging rain showers, inspected the subject to find the professionals had failed at the first hurdle - they had been unable to remove the o/s driveshaft (the only one attempted). Although there were no signs of clearing the muck out of the inhex bolts - there were three freshly rounded out heads (courtesy of windy gun I suspect).

Before welding a nut onto each of the problems (a bit near petrol and rubber!) I decided to try the "old fashioned way" and used verbal threats, a centre punch and a large hammer - took about an hour but success!.

Next - removal of the inner drive flange nut - my turn to fail - things a 36mm and no, of course I didn't have one with me!

Further report when I get a chance to return and continue.

Mac.

Re: "Professionals" huh!

Posted: 25 Oct 2015 06:18 pm

by 360beast

I've never seen a rear wheel bearing change on a 300 so I will definitely be keeping an eye on this, thanks for posting Mac.

Re: "Professionals" huh!

Posted: 25 Oct 2015 10:20 pm

by Logan360

I had to do a bearing once..... just swapped out the whole rear end lol.

Re: "Professionals" huh!

Posted: 26 Oct 2015 11:39 am

by volvomania

Professionally abused those bolts are, I would say

Good one Mac!

I have found that patience, a good clean of the bolts, a good Allen key and some soft swearing often works.

If not a clean freshly teethed vicegrip will help just to get them moving a few degrees.

No airtools however.

Re: "Professionals" huh!

Posted: 27 Oct 2015 02:33 pm

by Ride_on

Several versions covered here, mostly 360 and later 340:

viewtopic.php?f=54&t=10548

Re: "Professionals" huh!

Posted: 10 Nov 2015 11:49 pm

by SteveP

Nice work Mac! You could've put them in your ultrasonic cleaner before taking pics though

Re: "Professionals" huh!

Posted: 08 Dec 2015 08:12 pm

by mac

With life, the weather and everything getting in the way it's only last Friday that I managed to get across (45mls) to have another go at THE BEARINGS.

Last vist we had removed the driveshafts but were stymied by the lack of a 36mm socket. This visit brought it's own grief!

Despite both 12 and 6 point 36mm sockets and various breaker bars up to a metre in length we were quite unable to remove the inner flange retaining nut - not helped by position and the nut being extremely narrow on early cars.

After fahrting abaht for a couple of hours getting grumpier by the min. We gave up and decided the answer was to get the whole axle back to my workshop - so off with the axle (handbrake cables disconnected, torque rod disconnected, brake pipe off at the flexy, and four 10mm bolts each side) axle off and into the 4WD box.

Back at the Mac cave I set the axle up across the two woodworking vices in my wood shop.

Locked the hub flange and tried my longest bar, no joy! Tried my windy gun at 140psi. The nut laughed at me! Finally resorted to my MAPP torch and hey presto off came the nut!!

Now to draw of the inner drive flange - using a homemade puller the flange came off despite having been glued on with Locktite (270 I suspect).

Having expected the hub shaft to be tight (I had my slide hammer ready) I was surprised to find it tapped out quite easily with a copper hammer. 4 x 10mm bolts released the brake backplate and the alloy bearing carrier.

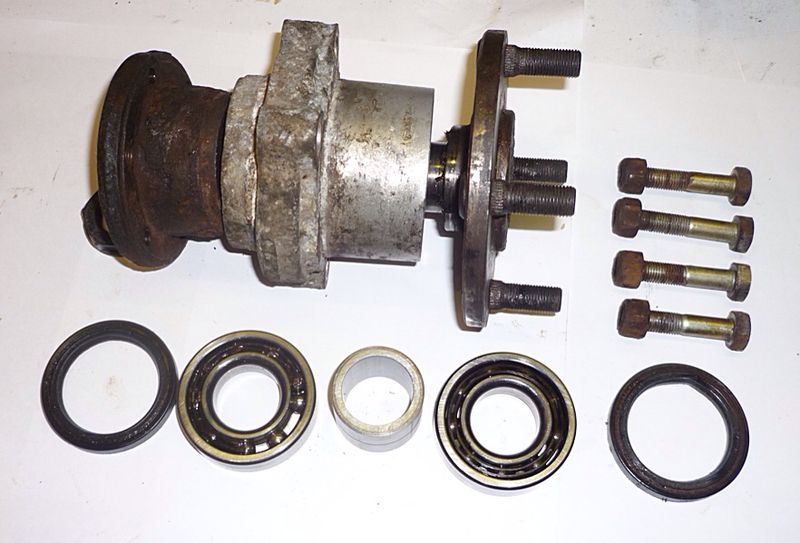

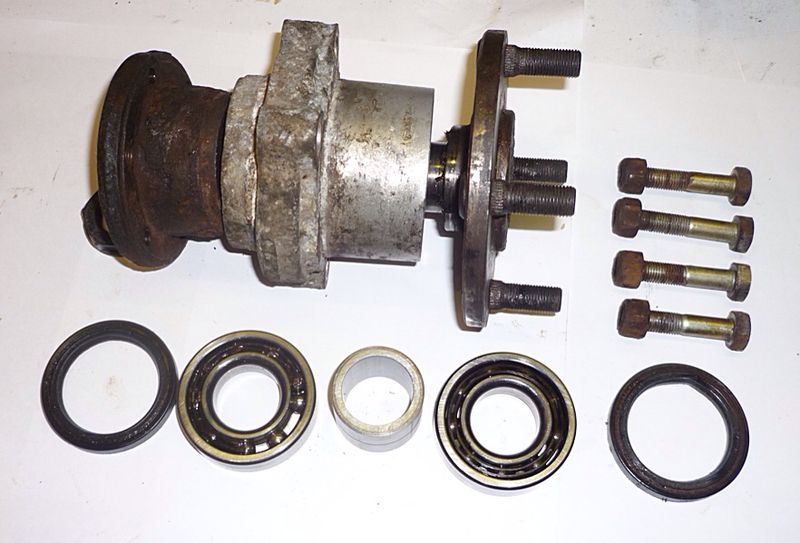

It was then a matter of removing the (2) ball bearings, seals and spacer from the housing - again it was necessary to heat the housing but otherwise no problem.

The ball bearings are conventional in design except for having widely spaced ball retained by a plastic positioning ring. The outer bearing was badly worn and very noisy but at least intact - the inner (no wonder it was rough and verrrry noisy) however had suffered breakage of the plastic ring a piece of which had been ground up to fragments!!

Other side to strip next!

To be continued!

Mac

Re: "Professionals" huh!

Posted: 08 Dec 2015 08:56 pm

by Ride_on

The early 345/343 seem to be a rear pain to remove this nut, I remember doing this in my 20s and it took pretty much everything I had, but I did do it on the car.

Re: "Professionals" huh!

Posted: 10 Dec 2015 10:00 am

by volvomania

Dutch stubornness left to mature for nearly 40 years

I suppose that you are loving it Mac....

Re: "Professionals" huh!

Posted: 10 Dec 2015 02:42 pm

by bogbasic

Excellent work, keep bearing up _{^¿^}_

Re: "Professionals" huh!

Posted: 10 Dec 2015 11:03 pm

by Hell Driver

Having dismantled a set of these from a scrap axle I can vouch for how awkward this job can be. (and I still had to take part to a blacksmiths to get a bolt drilled out which was absolutely seized in against the alloy). When it came to doing the one on the car (VFW) I took it to the garage I use for M.O.T.s. They managed it fine but it took the main man to sort it out as they younger mechanics had no idea how to tackle it. I know that he's familiar with older cars as is his dad who is now retired , they used to have all sorts in there.

Re: "Professionals" huh!

Posted: 10 Dec 2015 11:36 pm

by mac

Well the grief continues - dismantled the n/s today.

Nut came off OK - again using judicious heat, inner flange responded OK to my puller but shaft harder to drive out this time (actually used my slide hammer) - however the four bolts securing the bearing housing/backplate - yukkkkkk! One nut came off reasonably easily, one more with heat - the other two no chance.

Drilled off the heads to remove the backplate and then lots of heat and penetrating fluid - eventually could punch the bolt shafts out. Bearing carrier seized in axle plate - more heat and much copper hammering.

There was no way this was going to happen whilst still on the car!

The bearing carrier as removed,

Levering out the oil seals,

Eventually - in pieces at last,

The weekend promises clean and inspect parts - oh goody!

Mac.

Re: "Professionals" huh!

Posted: 12 Dec 2015 05:04 pm

by mac

And so Girls, the story continues!

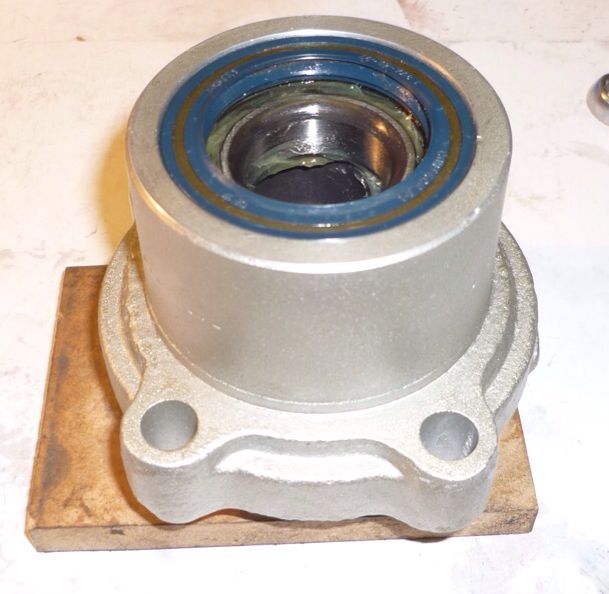

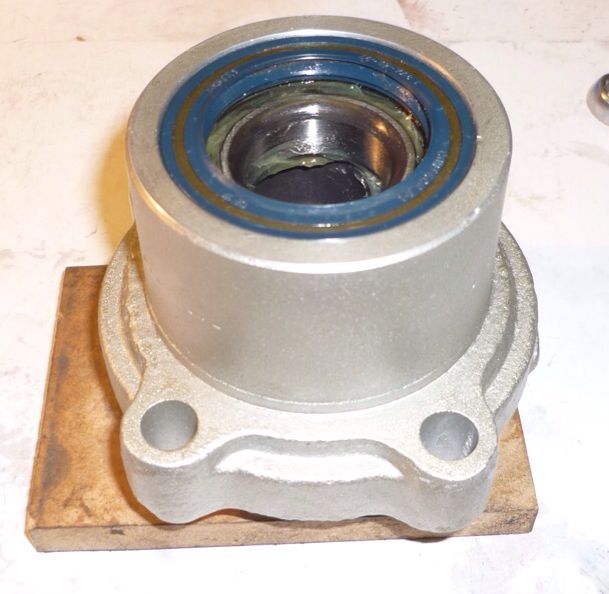

The n/s bearing carrier (the worst) was washed in spirits, glass bead blasted, cursed, dremallised with various wire brushes, ultrasonically washed and spray coated with Eastwood "Alumablast"

Spruced up rather well I fink,

The "customer" supplied the bearing kits - SKF boxes with FAG bearings in - humm, not seen other makes in SKF kits before - not that there is anything wrong with FAG (OE in the 300 anyway).

Bearings and seals all pressed in,

Now as a matter of interest - the OE and kit bearings are FAG 528606 deep groove single row 30x62x16 ball bearings that do not seem to be available in the UK any more (but I did find a supplier in Holland with them in stock still). However consulting an equivalence list the basic SKF 6206 / 362357 comes up. The 6206 is available in many forms both shielded and un shielded and with metal and plastic cages. At "Simply Bearings" us shielded plastic cage 6206s start at around £4 for a "no name" (but check the specs - there is a wide range of load and speed ratings).

The seals are standard 45x62x7 single lip jobbies available just about anywhere.

The bolts for the backplate/bearing carrier are M10x50x1.25.

Having de-rusted the backplate - apply jollup, (will be finished in chassis black),

Finally my best friend today when starting to dig the axle out from the rust - a needle gun!

Time for a brew - Mac

Re: "Professionals" huh!

Posted: 12 Dec 2015 08:45 pm

by bogbasic

Looks like an ale of a job, that does {^¿^}

Re: "Professionals" huh!

Posted: 12 Dec 2015 10:28 pm

by classicswede

Did the bearings come from me?

I have a few SKF sets like that and they all contain FAG branded bearings