340GLT wrote:I'm about to remove the ones from LFE, if i can get them off in one piece your welcome to them.

Adam

That'd be great if you could, Adam! The car's in the body shop right now, as the sills are being done ATM it'd be good if they could get the spring bracket done at the same time.

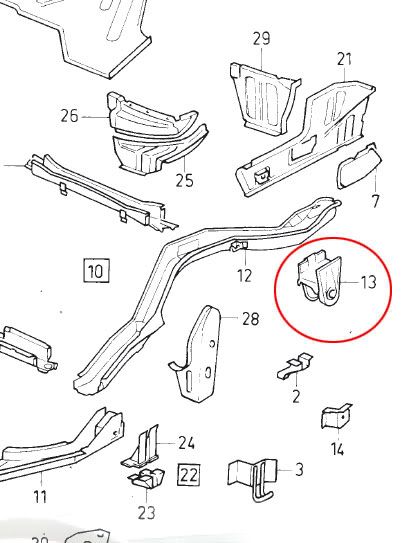

Ride_on wrote:Yes they are quite badly designed, I just been refurbing my RHS one (with the toeing eye). De-spot welded the box section from inside the boot then angle grinder cutter across the beam from the top and bottom. Plates are particularly hard to remove and full of compressed layered rust inbetween.

So if you are removing I recommend taking the box section aswell. Just angle grinder around the hole area from the top if recovering spare parts, spot welds nice and easy to see from insider the boot.

Another point I have noticed is that the outer plates seem to been designed to have water drain, but the lip on the inner bit blocks it off and it becomes a water trap, looks like a design boo-boo, but I doubt it would stop it rusting alot anyway. Most of the interior paint was poorly adhered, and very little cavity sealant in the box section. Looks like they had trouble getting the sealer gun in around the sides, very inconsistent.

Thanks for that, Rideon ... It seems the RHS is more prone to rust than the LHS for some reason, although the part is the same, in theory.

Cheers

Tom